I. INTRODUCTION TO WIN SYSTEM IN HIGH-SPEED

WIM (Weighing-in-Motion) was introduced at USA in 1950s, there has been a lot of differential developing steps and models in the world from that time. At the begging time, people install static weighing stations on roads for checking, identifying and forcing cut off goods on truck. However, after that, due to the developing of truck traffic while the performance of static weighing station is low. It causes the traffic jame at the Static weighing station.

WIM was used public over the world, from developing countries to developped countries. To year 2006, the number of lanes where were installed WIM at Northern USA is the most of the world (3.864 lanes), second is Asia (1.700), Latin USA (1.208 lanes), European (1.188), Australia (120), Africa (88) and Eastern Middle (56)

A WIN system consists of the following main components:

a/ The system of the sensor: load sensors, speed sensors, vehicle detection sensors, temperature sensors, license plates recognization sensors.

The load sensors are used the same principle called the principle of voltage, when the wheels rolling over the sensor systems, each different weight will be induced currents at different voltages. By its own calculation formulas, weight control panel will calculate the value and weight respectively.

b/ Weight control panel: Function collect sensor signals, signal processing, and provide basic values of vehicles and loads.

c/ Computer: Computers were connected to the signal control panel and carry out the work load calculation, storage and transmission of information according to different needs.

II/ THE LOAD SENSOR TECHNOLOGY SERVICES FOR WIN SYSTEM

At present, there are different types of technologies in the world, each technology is suitable for different speeds. Therefore, sensor technology is divided into 3 types: vehicles moving at slow, average, and high speed. Sensor technology used to measure vehicle weight in high-speed (high accuracy), but applying to measure vehicle weight in low speed is poor (incorrect) - and vice versa

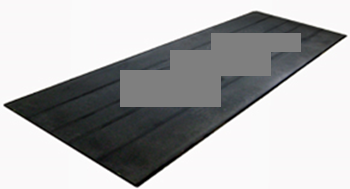

a/ Sesor measures vehicle weight in high speed (0..200km/ h) according to plastic sheet technology.

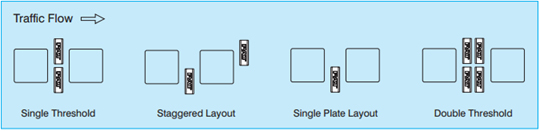

Each dedicated sensor plates have dimnsions up to 0.57 m x 1.95 m, which can be installed in 4 forms below. In addition, it's installed the detecting vehicle sensor to discover the presence of trucks, as well as the movement speed of the vehicle. Option 4 sensor is fitted with the lowest error.

a. b/ Sensor measures vehicle weight in high speed (1..200km/h) according to quartz technology.

Working principle: The core of the quartz sensor is constructed from pieces of quartz crystal. Runs through the sensor, wheel will affect on the quartz crystal by a vertical force without causing deformation. The pieces of quartz creates a piezoelectric charge output proportional to force.

Due to the material properties of quartz, piezoelectric sensitivity does not depend on the temperature, time, and speed. Electrical signal is converted into voltage signals by the converter. Accurate weight measurement is not dependent on the type of tire, the number of axles, or pressure of the wheel.

High accuracy when vehicle's moving than 10km / h

The downside of the quartz sensor is that vehicle stops on the sensor can not know its weight, or slowly moving vehicles under 10 km/h for high measurement error.

Under ideal conditions (laboratory conditions), the Wim quartz sensor system give measurement errors under 2%..

III/ INTEGRATED SOFTWARE SYSTEM

After getting the results of the load weight of the vehicle, the other integration is dependent on various specific applications.

The following is the app to warn the overloaded vehicles through the toll collection station.

Number plate recognition and vehicle weight classification:

When driving through toll collection system, camera will recognize number plates, taking pictures of the car and send all data to the vehicle weighing system, including: photographs, license plate, and load of vehicle.

Information of overload vehicles is immediately displayed on the screen:

Màn hình tổng quát – Hệ thống thực tế tại trạm thu phí quốc lộ do XPT cung cấp (nguồn tham khảo xpt.com.vn)

The patrol unit, force (inspector, traffic police) can use the software of weighing system anywhere as long as it can connect to a central server to get information of overload warning.